Context and Motivation

Situation

- Composite materials crucial for sustainable future

- Aircraft 50% or more out of FRP

- Wind energy sector with larger turbines

- Extreme loads and stress cycles during

- Damage tolerance needed to extend the lifespan

Challenge

- Lack of fundamental knowledge regarding damage growth process under cyclic loading

- Complex interaction of fibres, fibre orientation, and matrix materials

- Every new design requires multiple tests at various scales

- Imperfect solutions: high-safety factors, ‘no growth’ criterion

Consequence

Composites products are

- Expensive

- Labourious

- Inefficient to manufacture

NEED

A better understanding of the fatigue characterization at a meso-scale, so that we can scale up the gained insights to larger structures

D-STANDART intention

What?

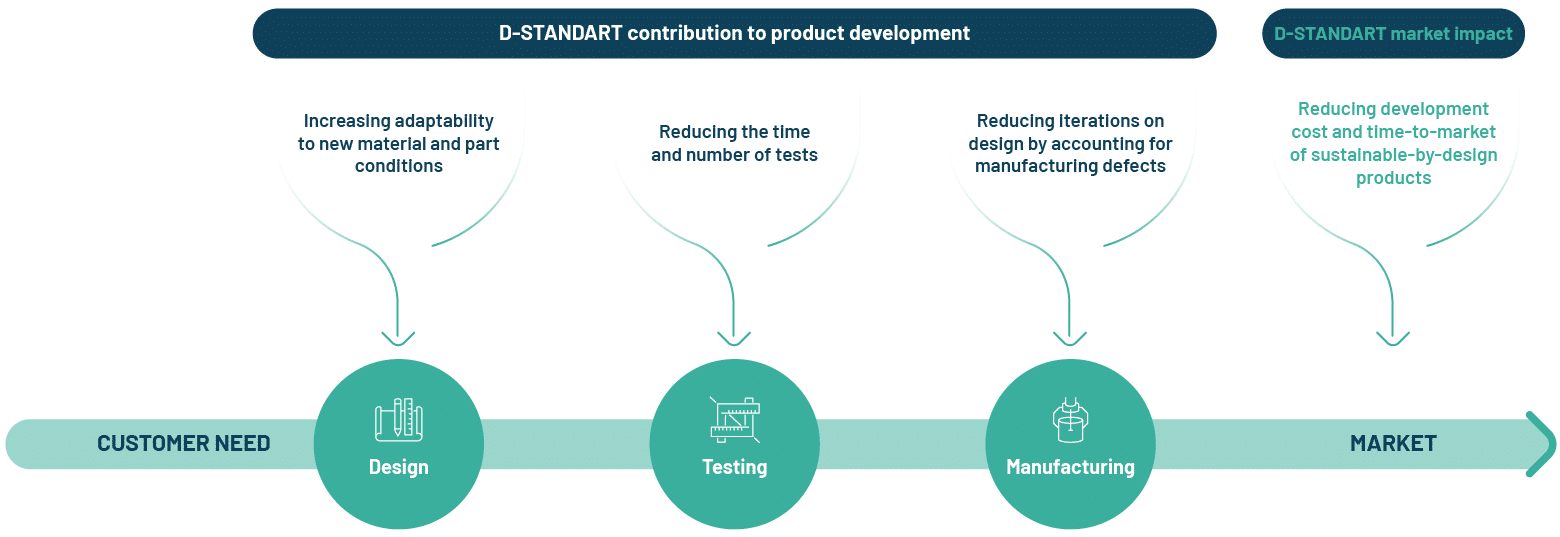

To develop fast and efficient methods to characterise the fatigue properties of composite materials, and thereby model the durability of large-scale composite structures with arbitrary lay-ups under realistic conditions (loads, environment, manufacturing/effect of defect)

How?

- Through minimal and accelerated testing of generic specimens

- Transferring the results of the experiments to large-scale structures using artificial intelligence and machine learning

Effect?

Enabling reduced time-to-market, material waste, and increased lifespan of composite products in the aerospace and wind energy industries