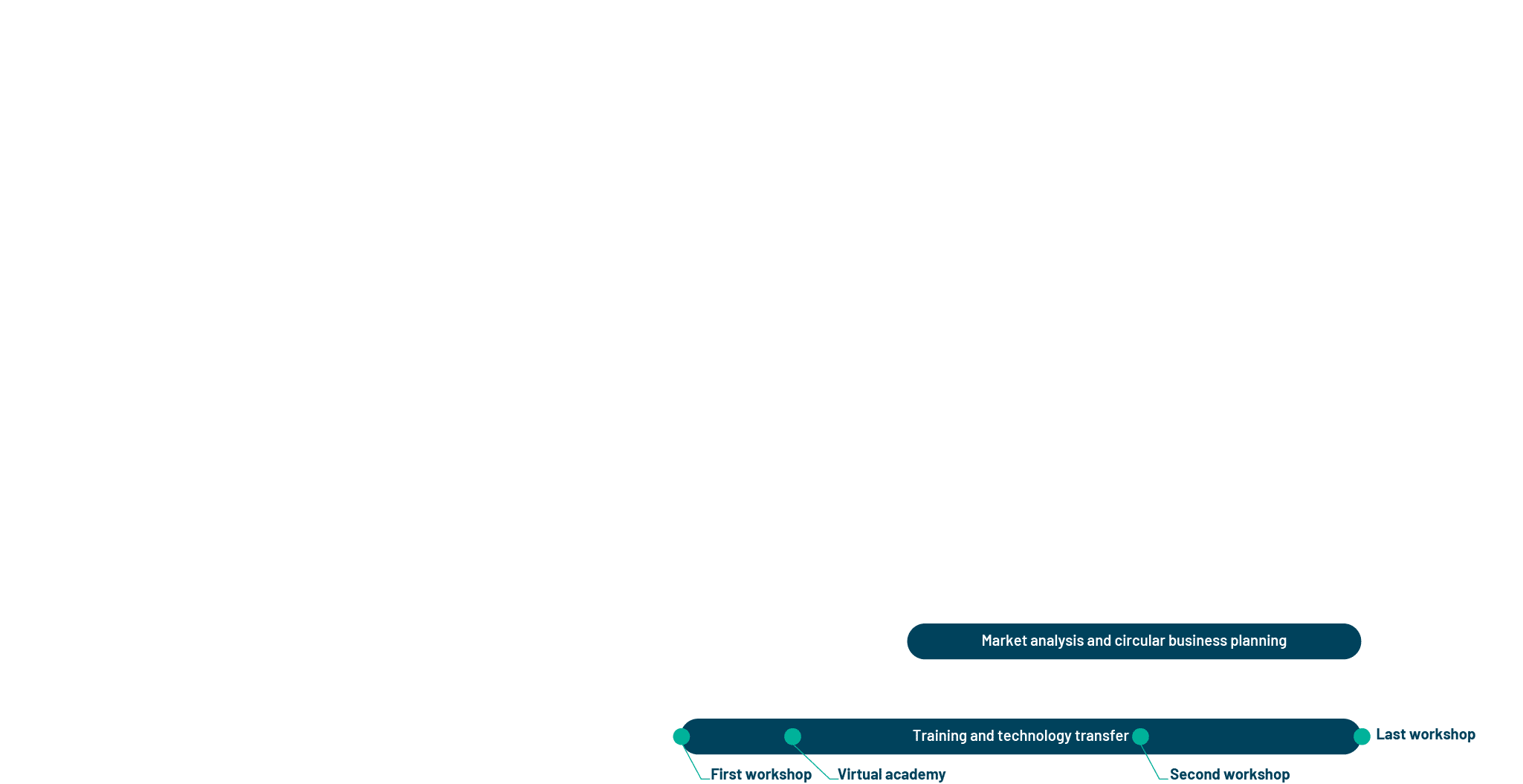

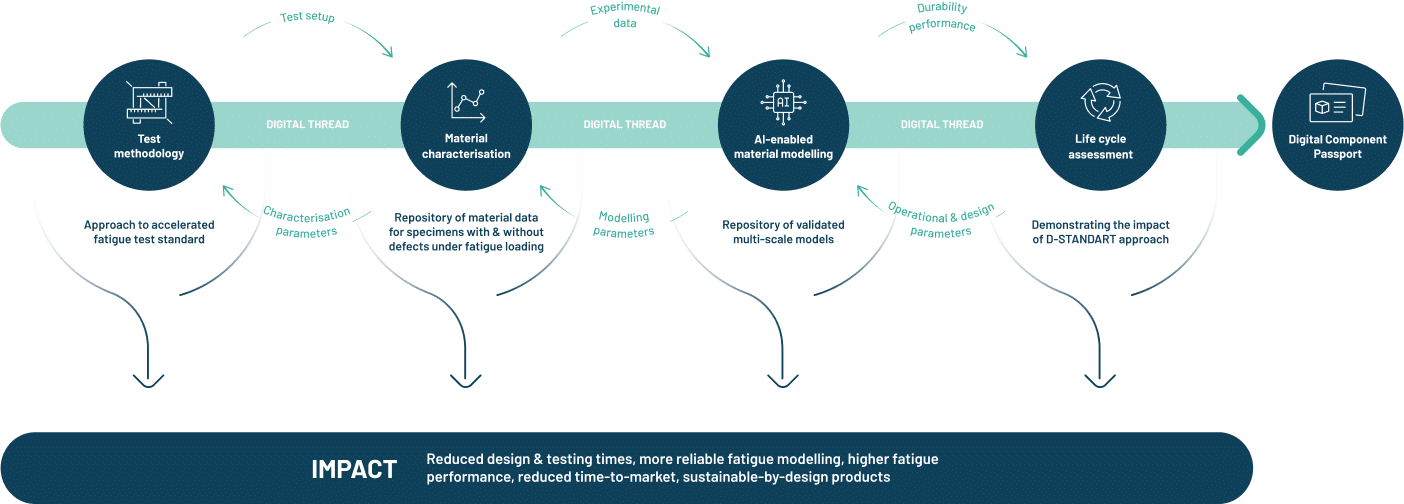

Overview of the approach

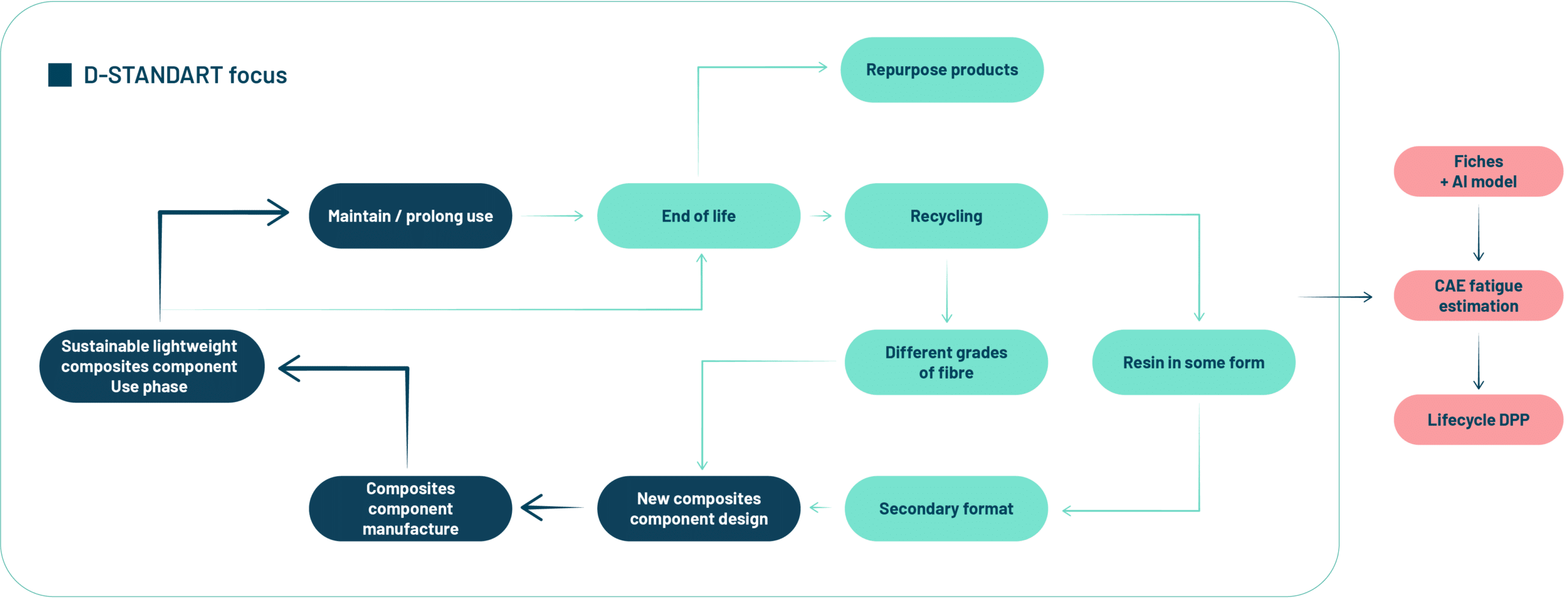

The D-STANDART project contributes to the development of sustainable lightweight composite products by designing fast and accurate testing methods that build a repository of material data. This characterisation data is used to train and advance multi-scale models which demonstrate the prediction capability of the durability performance and hence improved assessment of the product life cycle. Meanwhile the interfaces of these activities are supported by the digital thread, forming the foundation for a Digital Component Passport.

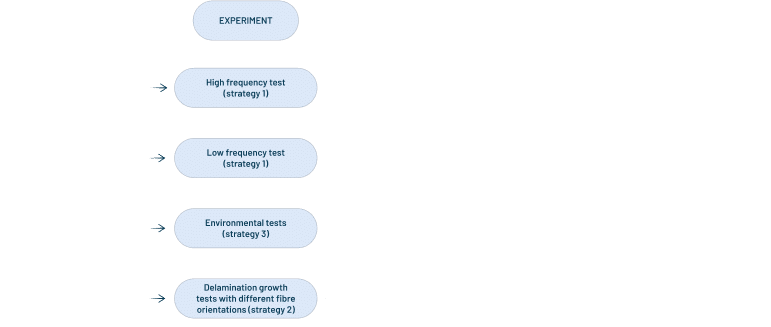

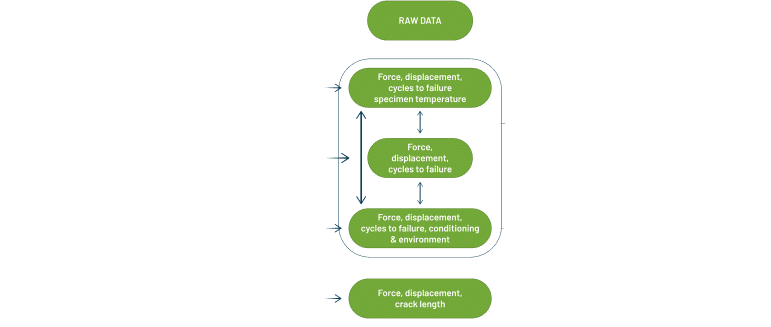

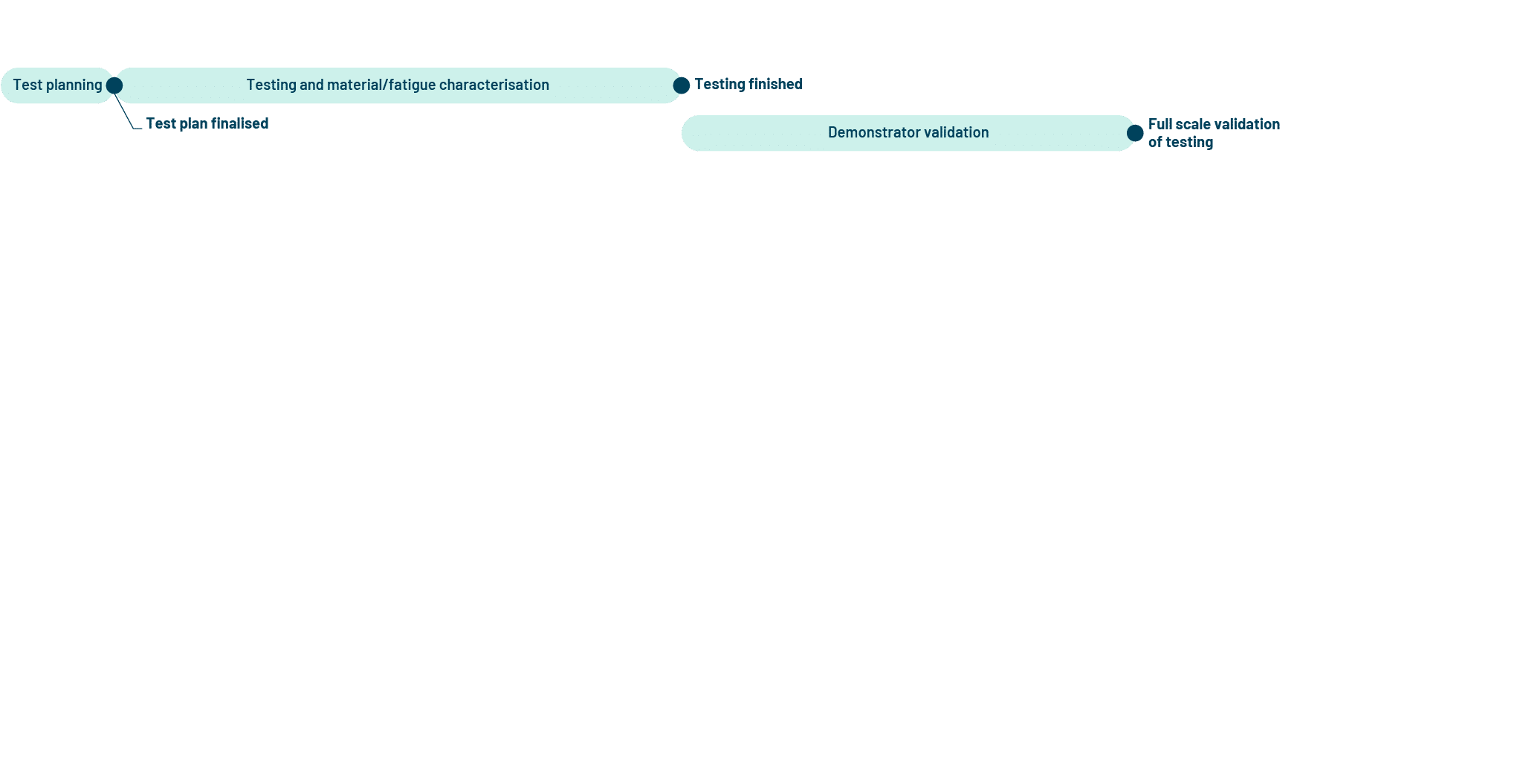

CHADA work flow:

Schematic overview of the test strategies

As first key activity in the approach, D-STANDART aims to radically reduce the test effort required to characterise the fatigue performance of composite materials. We will achieve this by a combination of three strategies:

- Developing a high-frequency test method, to drastically shorten the time required to complete a fatigue test.

- Developing a methodology for quantifying the effect of fibre orientation on fatigue damage growth. Inputting this data into the models we will develop will allow us to generalise test results generated on one specific lay-up to other lay-ups. This will limit the number of different lay-ups that need to be tested and enable better modelling of laminates containing steered fibres.

- Identifying the most efficient test methodology to generate the data needed to take environmental effects into account, with the minimum possible test effort.

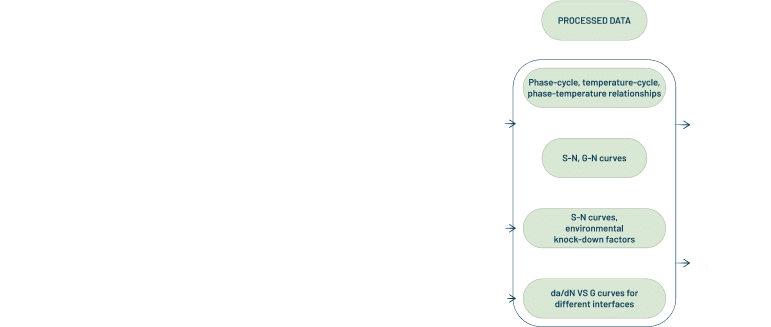

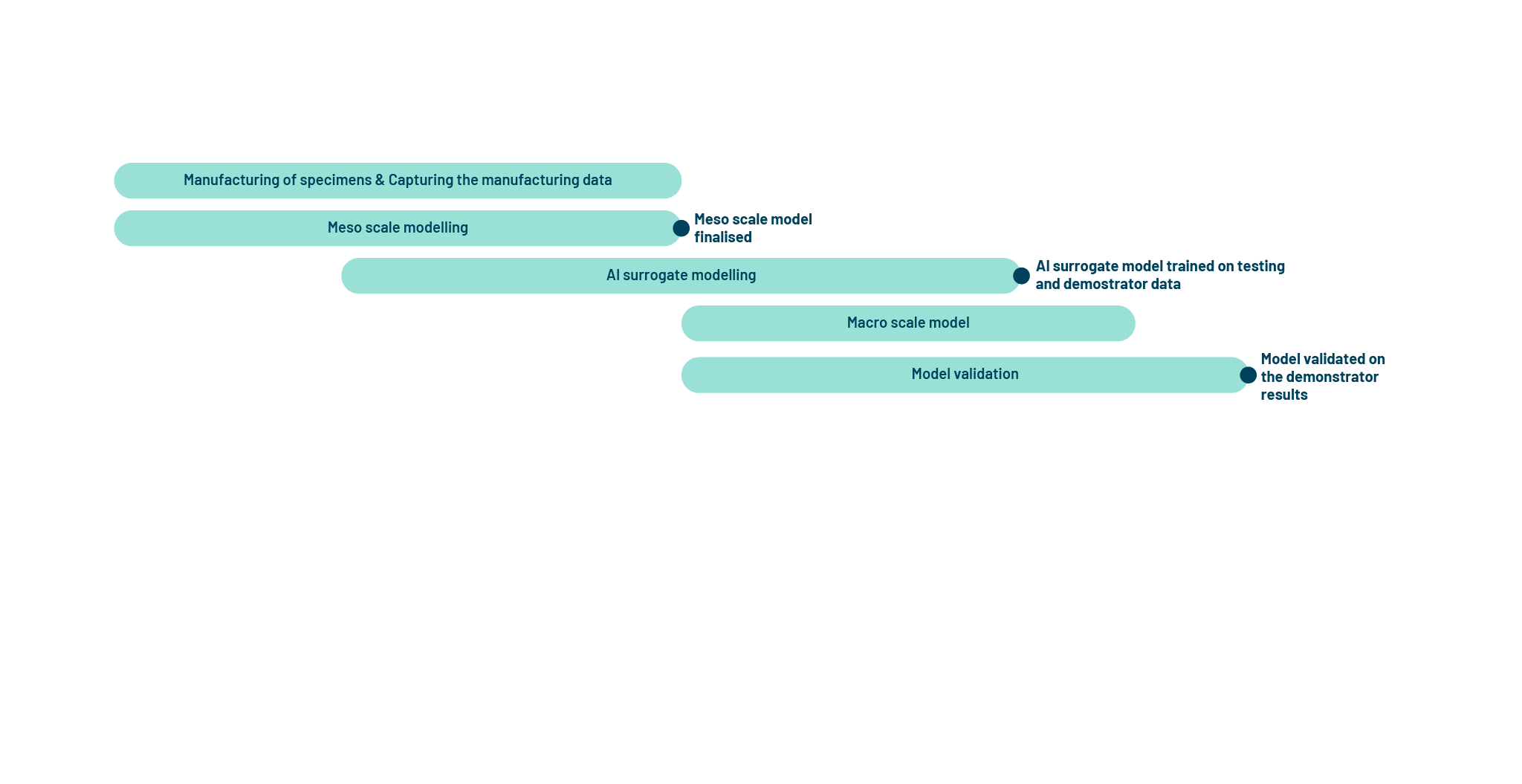

MODA workflow

Schematic overview of the modelling strategies

The methodology that underpins the AI-enabled material modelling entails the implementation and validation of finite-element based numerical techniques for the prediction of the performance of laminates.

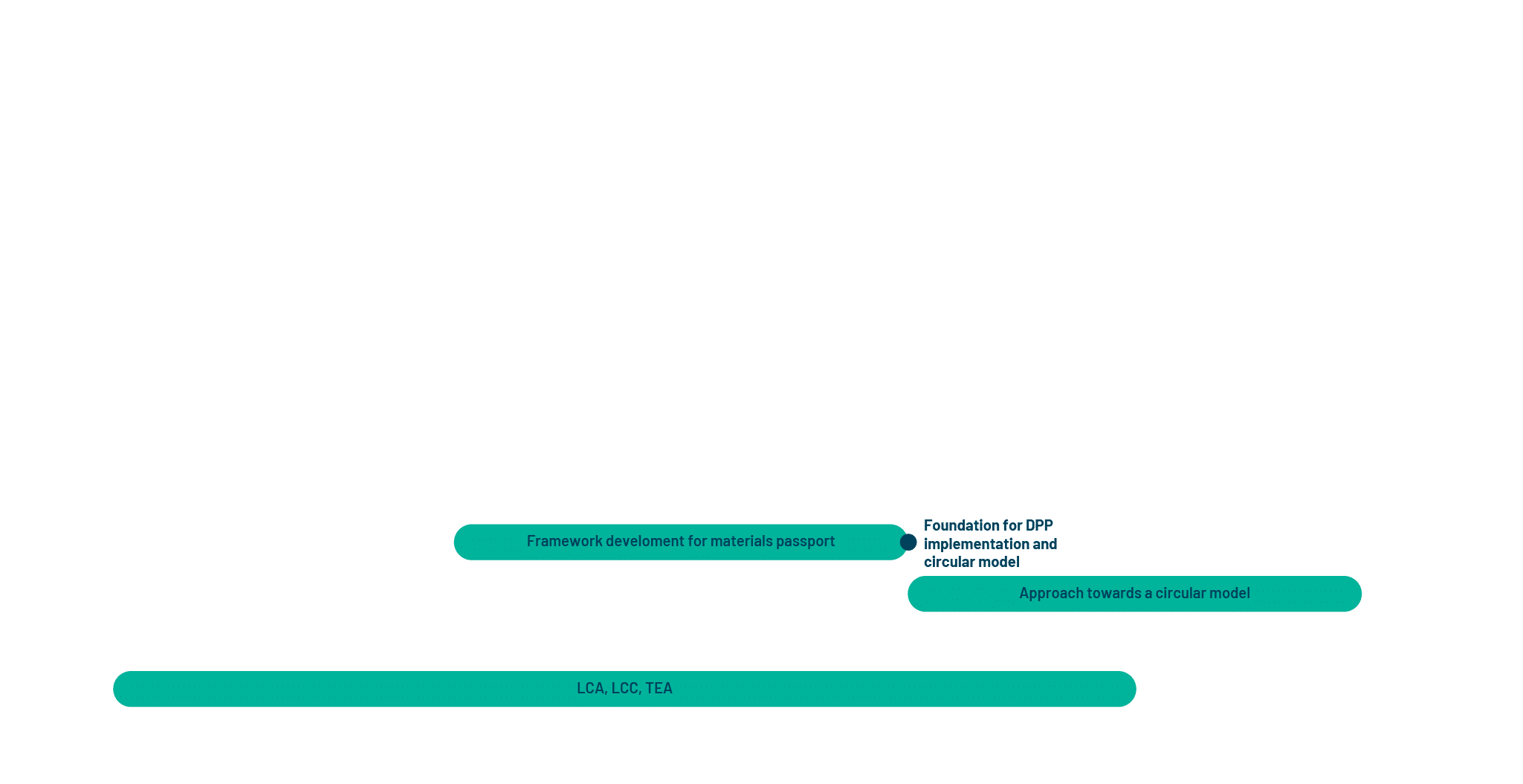

D-STANDART will finally provide a baseline calculation for environmental impact, material circularity, economic and social impact. This initial assessment will draw on information including Bills of Materials from the current materials and processes for the component, and identify ‘hotspots’ areas for improvement as the new design regime and traceability methods are put in place.

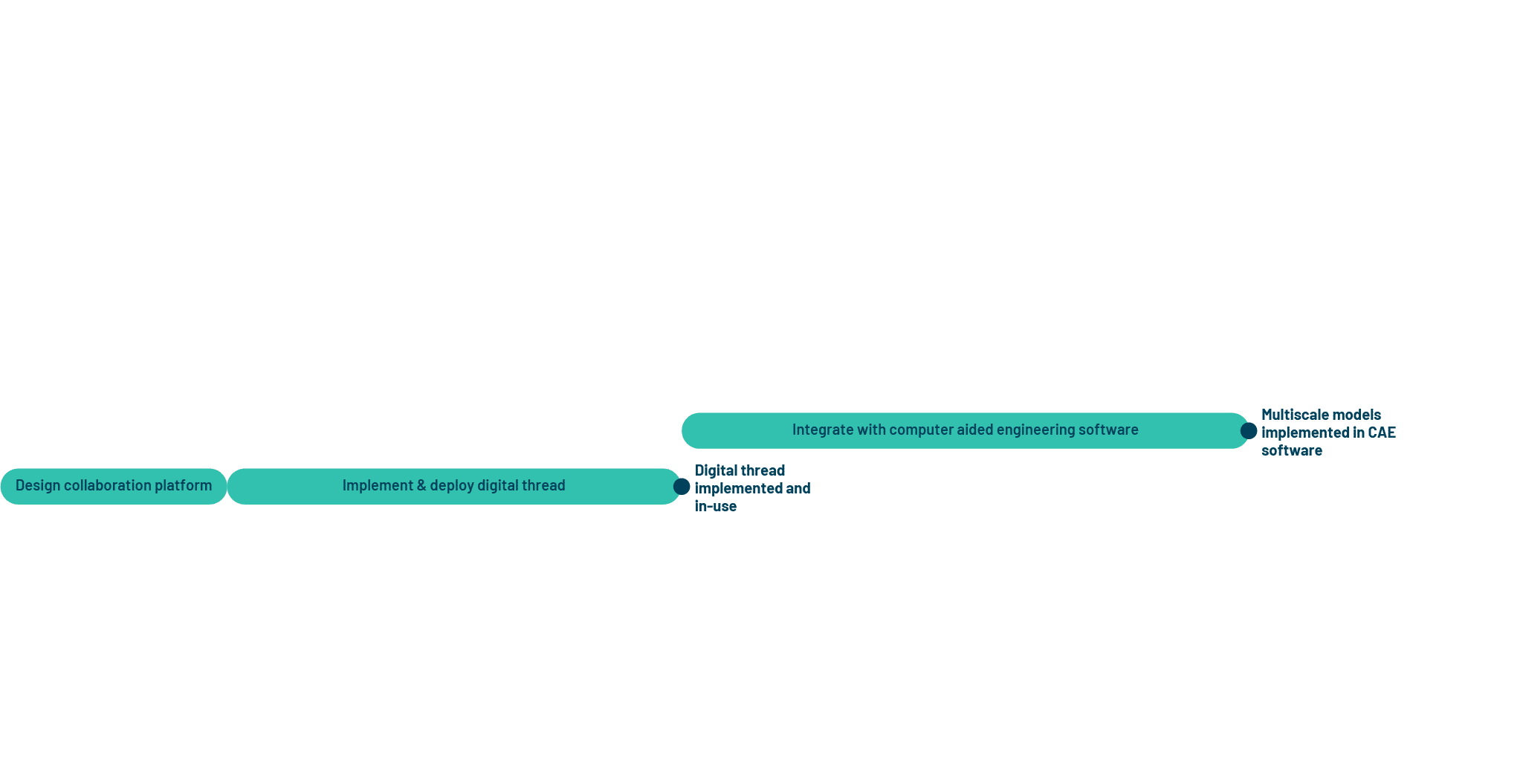

DIGITAL THREADS:

To support the lifecycle assessment conducted to demonstrate higher reliability of the design and sustainable use of material, and to identify and select standards that apply to the digital thread implementation, as well as to propose any relevant clarifications, enhancements, and possible extensions to the applicable standards, based on the digital thread implementation.